Comitrol® Processor Model 1700

Versatile Size Reduction

- Recommended for free-flowing dry and semi-dry applications.

- Maximum input product, in general, should not exceed 2.5" (63.5 mm) for 3" cutting heads; 3/8" (9.5 mm) to a slurry for microcut heads (depending on specific microcut head and impeller used); and 1/4 to 1/2" (6.4 to 12.7 mm) in any dimension (depending on impeller) for slicing heads.

- Available 15, 30, or 40 HP (11.2, 22.4, or 30 kW) motor.

- Sealed enclosure deters escape of dust, vapor, and liquid when the Model 1700 is installed in conjunction with a collection system.

- The machine features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance.

- HMI Option Now Available

HMI benefits include: identifies misaligned sensors, soft start faults and fixes, total machine runtime, motor loads and overfeeding issues, and remote start/stop when connected to a control center.

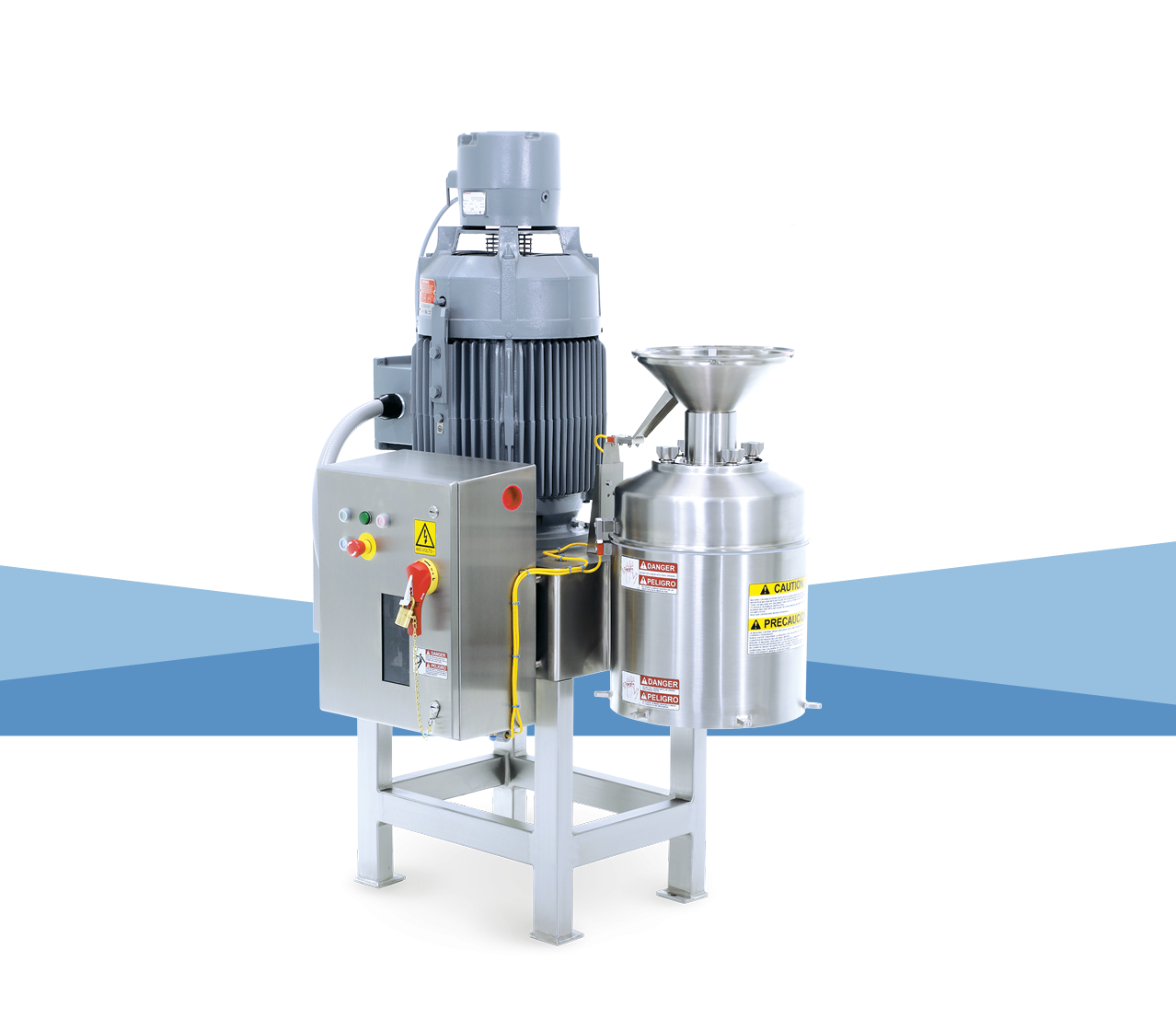

Applications

The Comitrol® Processor Model 1700 offers the most versatility in the Comitrol line. It utilizes 6" (152.4 mm) diameter reduction heads, available in the three different styles listed below. Product input is dependent on the style of reduction head, impeller selection, and spacing within the head. Generally, maximum input size in any dimension should not exceed:

Cutting Head: 2-1/2" (63.5 mm)

Microcut Head & Slicing Head: 3/8" (9.5 mm)

Sealed enclosure deters escape of dust, vapor, and liquid when the Comitrol Processor is installed in conjunction with a collection system. Stainless steel construction ensures maximum durability and sanitation. The machine features continuous operation for uninterrupted production, and is designed for easy cleanup and maintenance.

HMI Option Now Available

HMI benefits include: identifies misaligned sensors, soft start faults and fixes, total machine runtime, motor loads and overfeeding issues, and remote start/stop when connected to a control center.

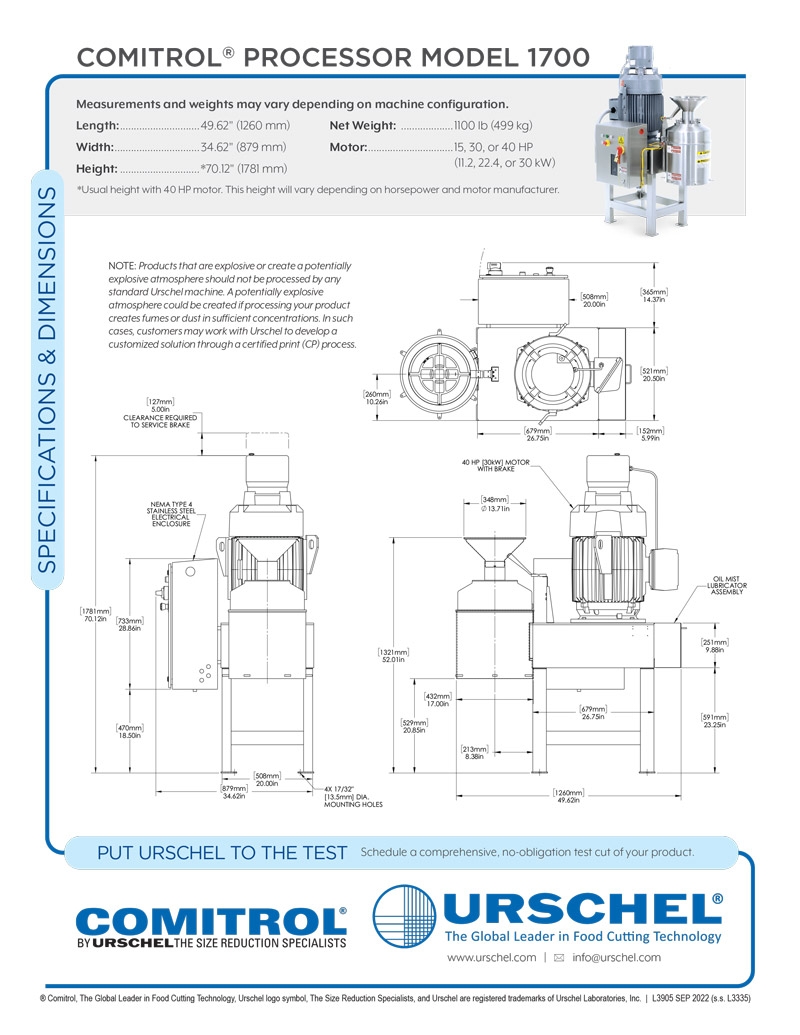

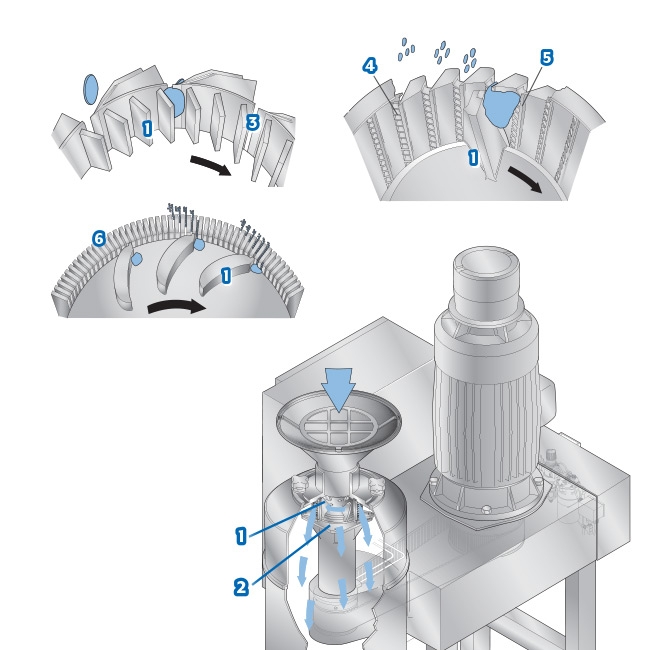

Operating Principle

Comitrol® Processor Model 1700

- Impeller

- Reduction Head

- Slicing Knife

- Horizontal Separators

- Vertical Knives

- Blades

Types of Cuts

Slicing Head

Slices: .020 to .060" (.5 to 1.5 mm).

Cutting Head

Offers particle size from .010 to 1.5" (.254 to 38.1 mm).

Microcut Head

Offers the smallest in particle size from .0012 to .0237" (.03 to .6 mm).

NOTE

Products that are explosive or create a potentially explosive atmosphere should not be processed by any standard Urschel machine. A potentially explosive atmosphere could be created if processing your product creates fumes or dust in sufficient concentrations. In such cases, customers may work with Urschel to develop a customized solution through a certified print (CP) process.